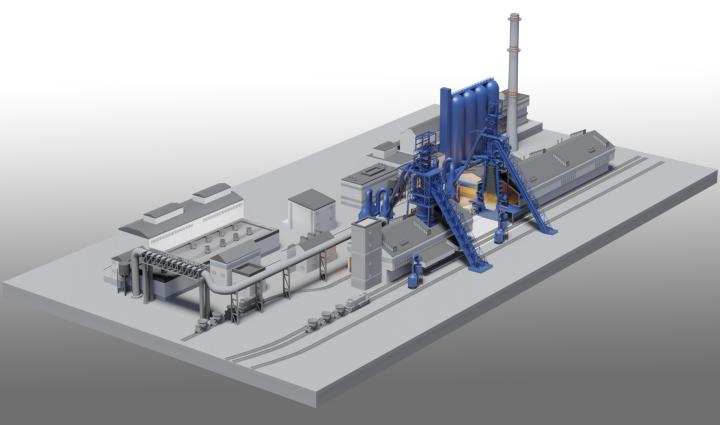

In blast furnace production, iron ore, coke and slag flux (limestone) are loaded from the top of the furnace, and preheated air is blown in from the tuyere located in the lower part of the furnace along the furnace.

At high temperatures, the carbon in coke (some blast furnaces also blow auxiliary fuels such as pulverized coal, heavy oil, natural gas, etc.) and the carbon monoxide and hydrogen generated by oxygen combustion into the air are removed from the oxygen in the iron ore during the rising process in the furnace, thus reducing the iron.

The molten iron is discharged from the iron mouth. The unreduced impurities in iron ore combine with the flux such as limestone to form slag, which is discharged from the slag mouth.

The resulting gas is discharged from the top of the furnace, and after dust removal, it is used as fuel for hot blast furnaces, reheating furnaces, coke ovens, boilers, etc. The main products of blast furnace smelting are pig iron, as well as by-products of blast furnace slag and blast furnace gas.