Shape and Dimension

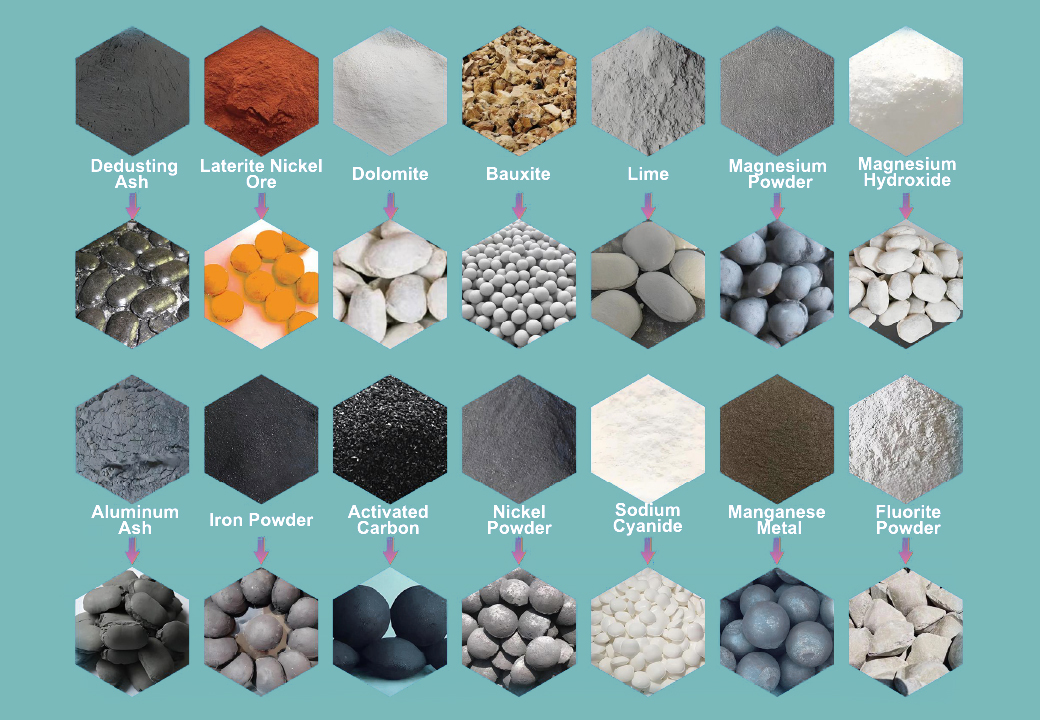

Ball socket’s shape in ball press machine’s roller sheet can be chosen widely according to user’s need.The ball’s shapes include pillow shape,semi-cylinder shape,egg shape,bar shape,thin skin pill shape,walnut shape,apricot core shape,smallparticle shape and so on.

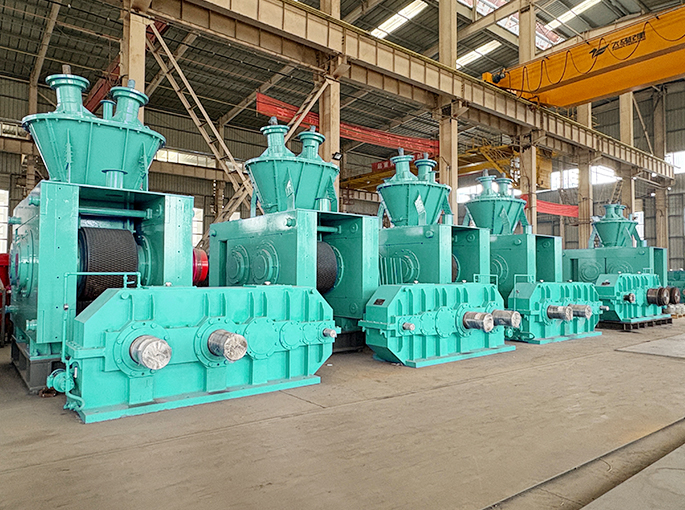

Our company’ s ball press machines are mainly divided into the following series: 750 series, 800 series, 850 series, and 1000 series. Equipment can be customized according to the different materials and production capacity requirements of users.