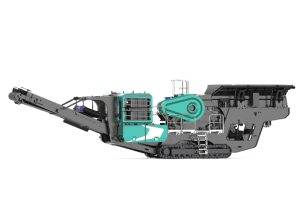

Working Principle

Afuruika mobile cone crusher adopts the material layering method to select the crushing cavity to fill the feed. The material undergoes all-round extrusion, shearing and kneading in the crushing cavity to achieve the purpose of crushing and self-crushing. The cavity wall avoids direct contact, effectively preventing the lining plates from wearing each other and preventing the material from being contaminated by metal pollutants, thereby reducing the number of easily worn parts of the machine and effectively extending the service life of the wear-resistant parts. Crushing comparison test More than double that of other similar devices.