working principle

Optimize the structure of the powder selection area and improve the efficiency of powder selection

The powder selection area is re-optimized to enlarge the space range, and the main space is fully utilized to increase the material-air ratio, which can increase the output of the open flow mill by 60%-80%, and the powder selection efficiency can reach 80%-85%.

Dust-proof and shock-absorbing design, easy to operate and maintain

The dust-proof and shock-absorbing fan is used, equipped with a shock-absorbing machine base, which can be directly supported by a steel frame. The installation is particularly convenient, the system investment is low, and the operation and maintenance are convenient.

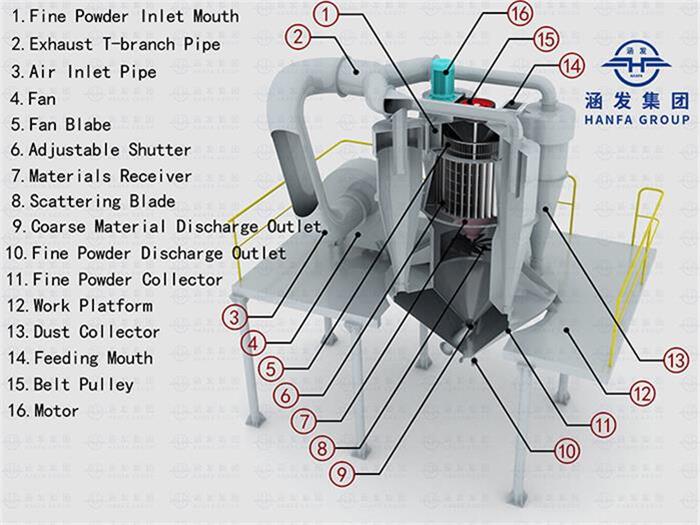

Equipment composition

The powder separator is mainly composed of shell, wind guide vane, rotating impeller, cone bucket and other parts.