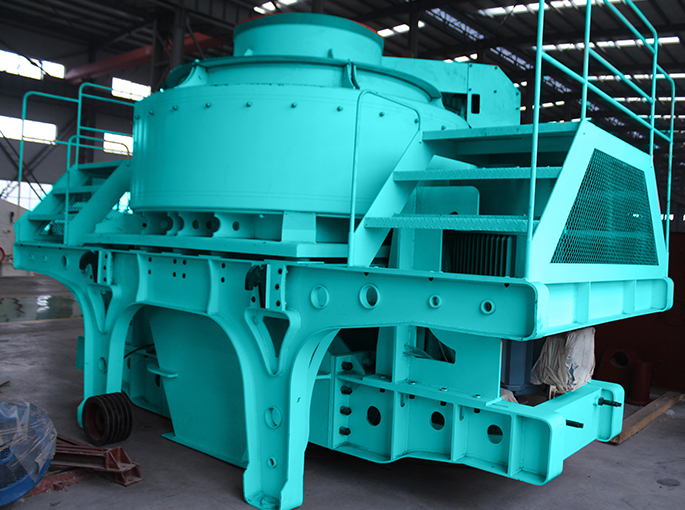

Working principle

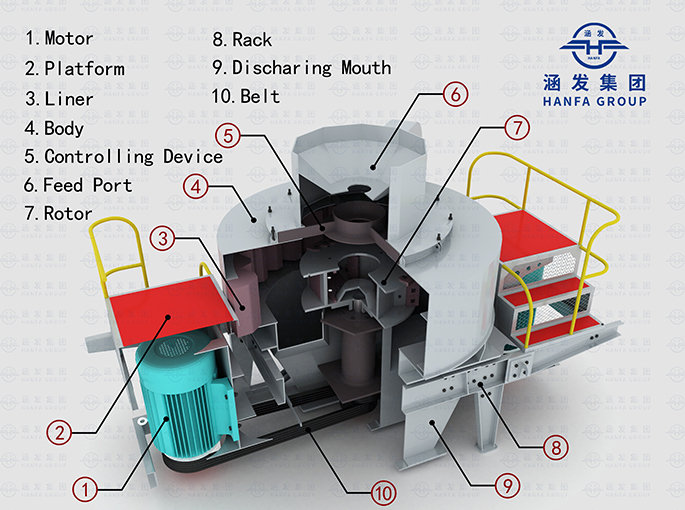

1. Feed raw materials: feed raw materials to be processed into the feed port of the sand making machine through the feeding device.

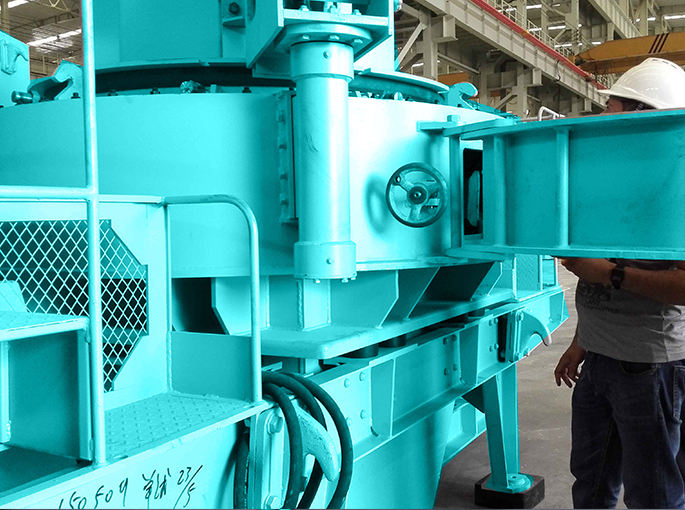

2. Crushing process: After the raw materials enter the sand making machine, the raw materials are subjected to strong impact and collision through the action of the high-speed rotating rotor and the impact plate. This causes the bulk of the material to break down into smaller particles.

3. Grading process: After the initial crushing, the gravel particles will further enter the screen or classifier for grading. As needed, the size of the sand can be controlled by adjusting the screen aperture or the speed of the classifier.

4. Re-crushing and plastic forming: Some larger particles may need to be re-broken to obtain the required fineness. At the same time, the sand making machine can also plastic form the particles through special design and device, so that it is more uniform and smooth.

5. Sand output: After crushing and plastic molding, the sand particles that meet the requirements will be discharged from the sand making machine through the discharge port to become the final artificial sand product.